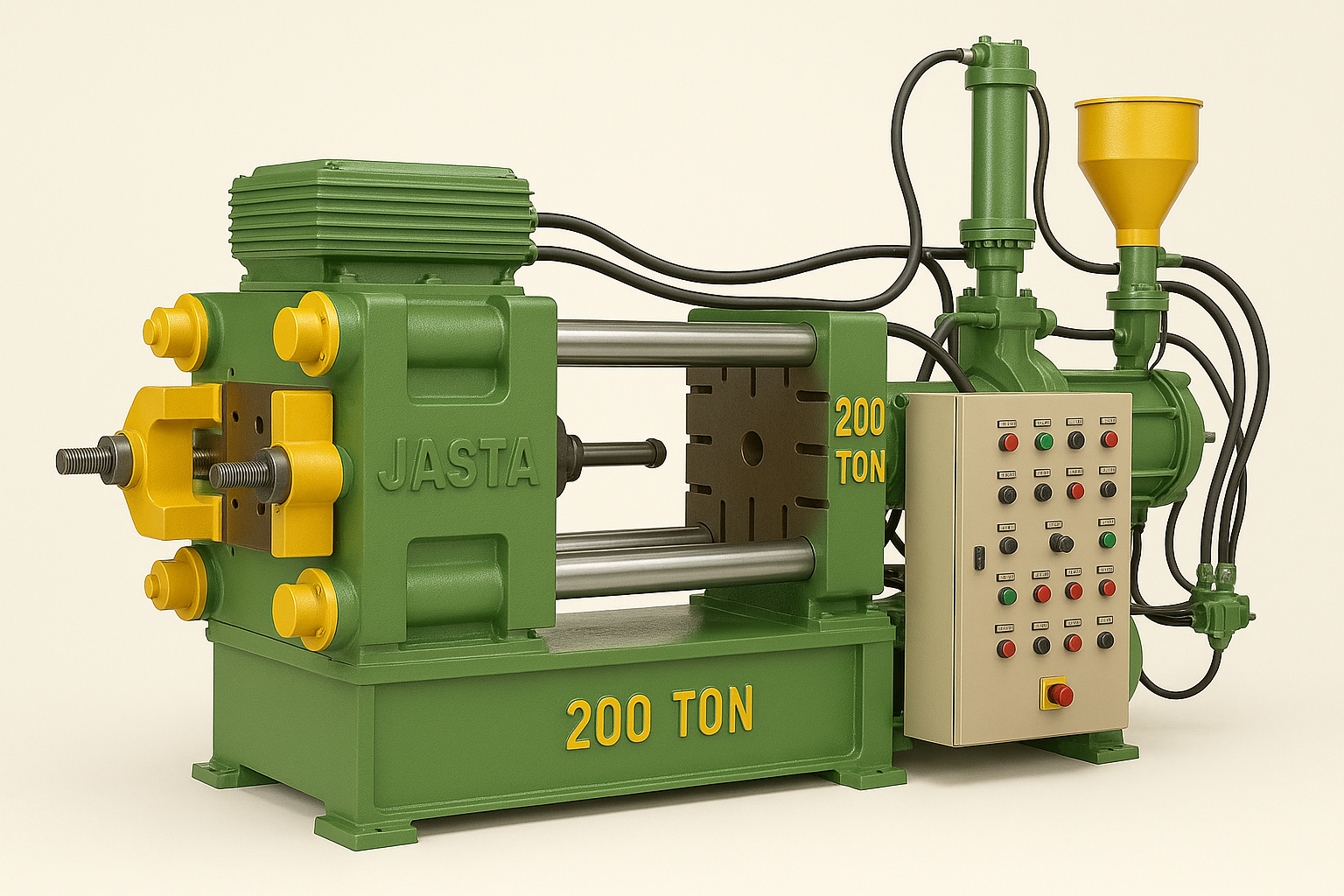

Die casting is a vital process in contemporary manufacturing, providing the capability of manufacturing intricate metal parts with incredible accuracy and efficiency. Out of the variety of available machines, the 200 Ton Jasta Die Casting Machine is notable for its powerful capabilities, particularly in automotive, aerospace, and industrial equipment manufacturing sectors. Nonetheless, purchasing a die casting machine is a considerable investment, and it must be done sensibly.

In this guide, we’ll explore key factors to keep in mind before purchasing a 200 Ton Jasta Die Casting Machine to ensure it meets your operational needs.

1. Understanding the Machine’s Capacity and Capabilities

The 200 Ton Jasta Die Casting Machine is built for medium to high-volume production runs. Its 200-ton clamping force makes it appropriate for casting parts of medium complexity and size. Before buying, determine your needs for production:

Component Size and Weight: Make sure the machine will accommodate your largest part. A 200-ton machine is perfect for engine casings, gearbox covers, and other medium-sized parts.

Material Compatibility: Ensure that the machine is compatible with the metals you intend to work with, for example, aluminum, zinc, or magnesium alloys.

2. Assess Your Production Volume

Think about your projected volume of production to see if a 200-ton machine is right for you. Large production facilities take advantage of the efficiency and speed of a Jasta machine, but if you need less, a lower-capacity machine could be cheaper.

Ask yourself:

How many parts do you need to manufacture on a daily or monthly basis?

Will the equipment be running continuously or in batches?

3. Evaluate the Space and Power Needs

Die casting equipment such as the 200 Ton Jasta is big and needs sufficient space for use and mounting. Take measurement of your working space and anticipate:

Machine Footprint: Ensure there is sufficient space for the machine, operator access, and ancillary hardware such as melting furnaces and cooling systems.

Power Supply: The equipment needs a stable and sufficient power supply. Ensure that your plant can handle its voltage and power requirement.

4. Automation and Control Features

Most modern die casting machines are supplied with automation and advanced control features to improve efficiency and accuracy. When considering the 200 Ton Jasta Die Casting Machine, look for:

Injection Control: Verify accurate controls of injection speed and pressure to guarantee uniform casting quality.

Temperature Monitoring: Search for real-time monitoring of mold and melt temperature to avoid defects.

Automation Options: Options such as robotic arms, lubrication systems that are automated, and mold-changing systems can make the process more productive and save on labor costs.

5. Maintenance and Serviceability

You should maintain your die casting machine regularly to ensure long-term performance. Consider the following:

Ease of Maintenance: Parts that are easy to access and modules that are based on modular designs make maintenance easier.

Availability of Spare Parts: Ensure that replacement parts are readily available for the model you’re purchasing.

Technical Support: Choose a supplier with a strong service network for prompt repairs and support.

6. Cost and Financing

A 200-ton die casting machine represents a significant investment. While the price of the machine itself is a major factor, don’t overlook additional costs:

- Installation and setup

- Training for operators

- Ancillary equipment (e.g., cooling systems, conveyors)

- Maintenance and operational expenses

If cost is a factor, ask if there are options for financing or second-hand equipment.

7. Manufacturer Reputation

The Jasta name is famous for its dependability and accuracy engineering. It’s still important to research, though:

- Customer Reviews: Find comments from other companies who use the same machine model.

- Manufacturer’s Track Record: A manufacturer with a reputation for meeting customer needs and delivering innovative products is a better bet.

8. Adherence to Safety and Environmental Regulations

Make sure the machine meets industry standards for safety and environmental regulations. The 200 Ton Jasta Die Casting Machine ought to incorporate safety interlocks, emergency stops, and low emissions to meet international and local standards.

9. Training and Expertise

Running a 200 Ton Jasta Die Casting Machine needs experienced staff. Verify whether the supplier or producer provides training services for your operators. Properly trained operators can heavily enhance the machine’s efficiency and longevity.

Also Visit : Quick guide to adjusting settings on a 160 ton jasta die cast

Conclusion

The purchase of a 200 Ton Jasta Die Casting Machine is a calculated investment that can revolutionize your manufacturing capacity. If you take the time to scrutinize the factors like capacity, production requirements, space, automation, and cost, you can make a well-informed choice that suits your company’s objectives.

At Radhe Industries India, we take pride in helping companies choose the correct equipment for their requirements. With our in-depth knowledge of die casting machines, you are not only getting a machine, but a solution that will lead to growth.

For details of die casting solutions or to see what products we have, visit radheindustriesindia.com today!