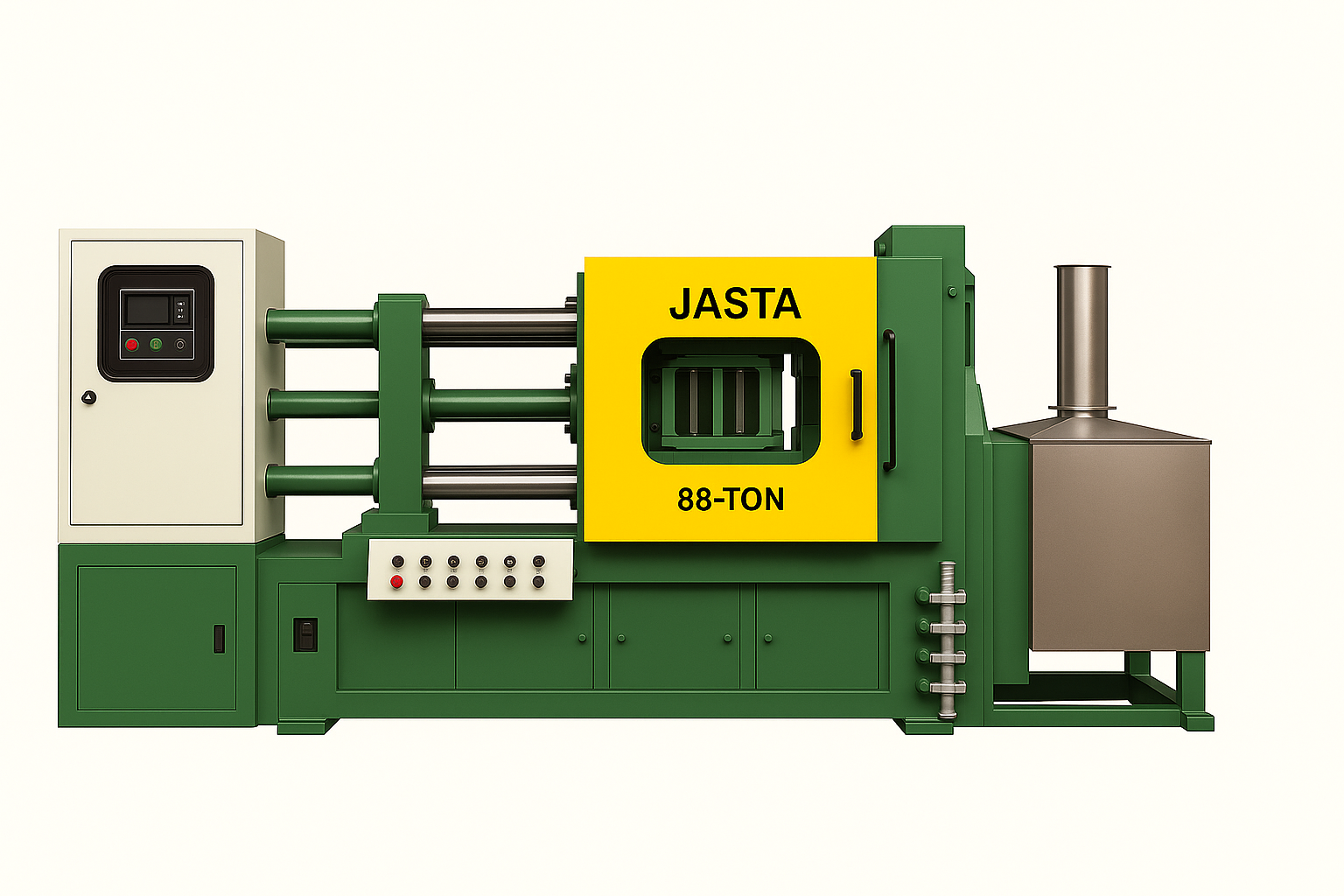

In modern manufacturing processes, the key requirements are precision, efficiency, and uniformity. For the die-casting industry, these requirements are made easier by one part, the 88-ton Jasta Die Casting Machine. Knowing the potential of this piece of equipment can help you make more informed decisions in production, regardless of whether you are in the automotive, electronics, or industrial components manufacturing industries.

In this article, we will detail the 88-ton Jasta Die Casting Machine, its relative importance in particular sectors, its main specifications, and its applications to analyze the value it bears throughout different industries.

What is an 88-ton Jasta Die Casting Machine?

The hot chamber die-casting method uses zinc, magnesium, and lead alloys as some of the non-ferrous metals. Jasta’s medium-capacity machine, the 88-ton Jasta Die Casting Machine, falls under this category. Non-ferrous metals” define the categories of raw materials. These metals include zinc, magnesium, and lead alloys. The clamping force is also stated in the form of a numeral: 80-ton which depicts the torque created due to the rotation of a lever between the casted janitor and employees.

With this type of clamping pressure, raw materials are processed to form parts made of precision composites having excellent surface quality, controlled porosity, posh per volume, and high precision along with their geometric features. This model is designed to suit the mid-sized portion of the market and is most suitable for producing goods in large quantities. Jasta is known for casting machines of medium to high complexity offered at competitive prices with a tolerable lifetime expectancy.

Technical Specifications of the Jasta 88-Ton Machine

Let’s take a look at some of the standard technical features:

Estimated Platen Size: Exceeds or is equal to 400 x 400 mm and less than or equal to 600 x 600 mm

- Injection Pressure: Stays between 30 MPa and 80 MPa

- Die Height: Changeable from one die height to any other die height

- Hydraulic System: With energy-saving servo or variable displacement pumps

- Control System: Touch panel with PLC-based control system

- Safety Features: Emergency shutdown, safety gates, interlocks, pressure sensors.

Due to these features, this machine becomes the ideal choice for manufacturers focusing on economical production of components which are small to medium in size.

General Industrial Uses

This 88-ton die-casting machine is popularly used across industries for sophisticated metal parts due to its fine tolerances and smooth finishing.

1. Automobile Industry

- Sensor and actuator housing

- Gearbox bearings

- Internal mountings and brackets

2. Electrical & Electronics

- Transformers

- Heat-sinks

- Cable connectors

3. Hardware & Tools

- Furnishings of doors and windows

- Hand tools

- Pieces for locks

4. Consumer Goods

- Bathroom accessories

- Decorative Hardware

- Electronic enclosure

This machine is the most efficient for the easy production of small parts due to its compactness, lightweight, and help of the CNC facility.

Benefits of the Jasta 88-Ton Die Casting Machine

1. Consistency and Repeatability with Accuracy

Due to modern hydraulics and effective mold opening and closing, every single cycle yields the same result.

2. Cost of Production Optimization

When the cycles become repetitive, and reduced material spillage occurs, efficiency improves significantly.

3. Space-efficient Design

This is ideal for workshops with constraints concerning space as the machine’s footprint is contained.

4. Easy maintenance

Components within the Jasta Machines are accessible which makes them easy to maintain.

5. Energy efficiency

Reduced energy usage by modern hydraulic systems when compared to older models is by 40% which makes them more efficient.

Industry Insights: Why Choose a Jasta 88-Ton Machine?

Jasta has been a front runner in the Indian die-casting industry when it comes to customization and performance features in their machines. The 88-ton die-casting machine is a favorite among mid-sized businesses that want a reliable first step into semi-automated or automated die-casting.

This machine helps manufacturers keep pace with competition with its ability to produce lightweight and durable components for automotive and consumer goods.

Also Read: Best 40-Ton Jasta Die Casting Machine: Specifications, Applications, and Price Guide

Conclusion

The 88-ton Jasta Die-Casting Machine is more than a tool; it is an asset for investment oriented on precision manufacturing. Its robust construction, high repeatability, and easy-to-use design means it is a preferred choice for small to mid-scale enterprises.

For new entrants in the die-casting business, knowing the features and benefits of this machine is the key to making smart decisions for production. Existing operators looking to upgrade their facilities also stand to benefit from understanding the advantages of the machine.