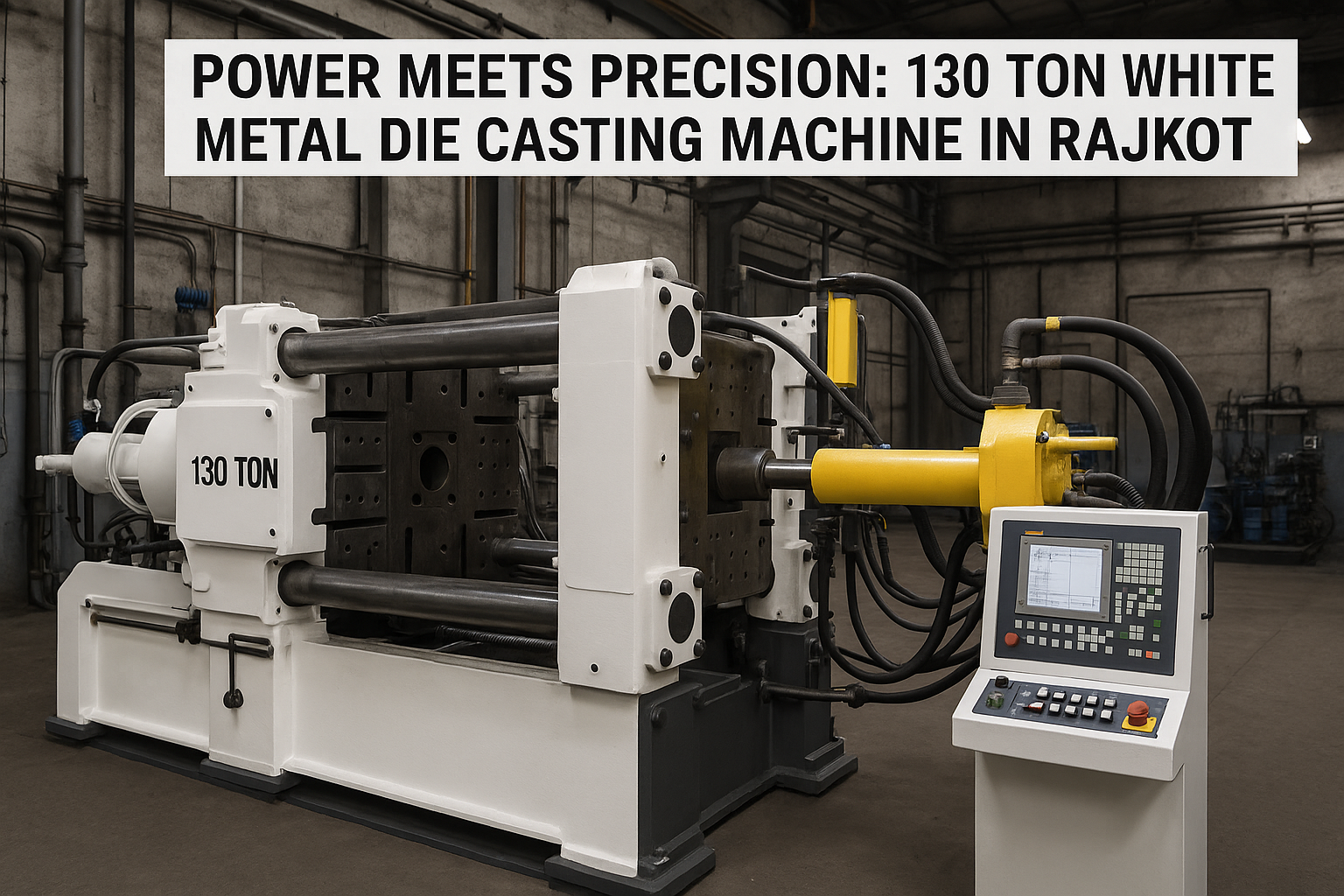

Rajkot, long celebrated as a hub of engineering talent, still stands as one of India’s hardest-working manufacturing cities. A key player in its shop floors is the 130-ton White Metal Die Casting Machine—heavy-duty, high-speed, and built for exacting volume. Whether turning out car parts, motor brackets, or everyday industrial fixtures, the machine helps local firms cut scrap while lifting quality.

The post that follows will break down the unit’s strength, speed, and accuracy, and show why it has become a must-have in today’s metal casting plants.

What Is a 130-Ton White-Metal Die-Casting Machine?

A white-metal die-casting machine makes close-fitting metal parts by pushing molten alloy at high pressure into steel molds that can be used over and over. The 130-ton rating tells you how strong the clamping force is, keeping the mold shut tight while the liquid cools, which is the key to casts that look good and measure true.

That power is just right for mid sized pieces that need toughness, accuracy, and a clean surface. It serves manufacturers in: automotive; consumer electronics; home hardware; medical devices; precision instruments.

Why Rajkot Is the Right Place for Die-Casting Excellence

Rajkot has earned its stripes as a go-to center for machine tools, casting gear, and metal engineering. Thanks to a sharp, experienced workforce, ready-made industrial estates, and steady raw-material supplies, the city rolls out the perfect backdrop for running top-tier machines such as the 130-ton White Metal Die-Casting press.

Firms in Rajkot lean on this powerhouse to meet the fast-rising demand for:

- High-volume runs that still pass strict quality checks

- Quicker cycles and bigger output

- Tailored parts that serve a wide range of markets

Key Features of the 130-Ton Die-Casting Machine

Let’s dive into the traits that have made this press a favorite on shop floors:

1. High Clamping Force

With 130 tons behind it, the mold stays locked, cutting flash, porosity, and warping.

2. Precision Control System

A user-friendly PLC and touch screen let operators watch and tweak every pour in real-time.

3. Energy-Efficient Operation

Smart hydraulics and gentle pressure keep bills low and fit with modern green goals.

4. Durable Build Quality

Heavy steel and first-rate parts let the press run around the clock with little fuss.

5. Fast Cycle Times

Quick opens and closes boosts output, shrinks downtime and feeds the bottom line.

Applications and Industries Benefiting from the 130-Ton Machine

White-metal casting is so flexible that it crosses into several sectors, and the 130-ton model plays a big part. Shops that run this press now turn out:

- automotive housings and brackets

- electrical connectors and other parts

- frames for medical devices

- components for household appliances

- plumbing and sanitary fittings

Thanks to the machine’s steadiness, Rajkot firms are shipping reliable goods to buyers at home and overseas.

Also Read: 88 Ton White Metal Die Casting Machine in Delhi: Power & Precision for Modern Manufacturing

Final Thoughts

For any manufacturer set on growing production without losing the tight tolerances and consistent quality every job demands, the 130-ton White Metal die-casting machine now operating in Rajkot could prove a real turning point. It blends solid engineering, speed on the shop floor, and a sensible price tag into a single purchase that will keep paying dividends long after the initial setup.

Whether you are already in the casting trade or yet to step in, this piece of equipment shows in practical terms how power meets precision in one of India’s most forward-looking industrial hubs.